Pipeline Equipment

Pipeline Pigging Products

Creating a line of flexible open cell polyurethane foam pigs that have the ability to negotiate short radius bends, ells, tees, multi-dimensional piping and reduced port valves.

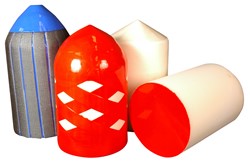

Maloney Pipeline & Prover Spheres

Compression Molded for Optimum Resiliency and Wear-Resistance

- Pipeline Spheres & Pigs

- Line Markers

- Casing Insulators

Inline Services

Inline Services has a wealth of experience in supplying products and services for pipeline cleaning. They maintain a comprehensive inventory of pigging equipment.

Inline Services has a wealth of experience in supplying products and services for pipeline cleaning. They maintain a comprehensive inventory of pigging equipment.

Their consulting engineers are highly qualified in the management of pigging and pipeline maintenance applications including regular cleaning programs, corrosion problems including pitting and scaling and removal of troublesome deposits such as black powder, liquids and waxes.

Girard Industries

Hosting a full line of pipeline pigs including steel mandrel pigs, polyurethane spheres, poly pigs, solid cast polyurethane pigs and replacement cups and discs.

Omntec

Accurate interface detection is the key to reducing transmix. Omntec uses an inherently safe refractive index instrument to detect product changes more accurately than density measurements. The fiber optic cable allows the sensor to be mounted up to 2km away from the receiver.

309.451.0825

309.451.0825